Benefits of Optimization on Supply Chain Logistics

I write up this piece to explain how I adapted the scientific information to a real-life problem by using the approaches and methods I learned from an online course and the benefits to me as well as the company.

My motivations to write up this piece are:

- Defining order picking problem in a warehouse for a logistics firm

- Giving information about an online course by taking advantage of scientific approaches to implement solutions that include rule-based and heuristic algorithms in the retail sector

Problem Definition

The products are shipped from warehouse to the stores in order to replenish the products which are sold or the new season daily. When a plenty of stores demand a product which has limited stock, there occurs an optimization problem including which product to assign to which stores and generating the tours (work order) which has minimum picking time inner warehouse. These two parts of optimization problem are required to be solved simultaneously.

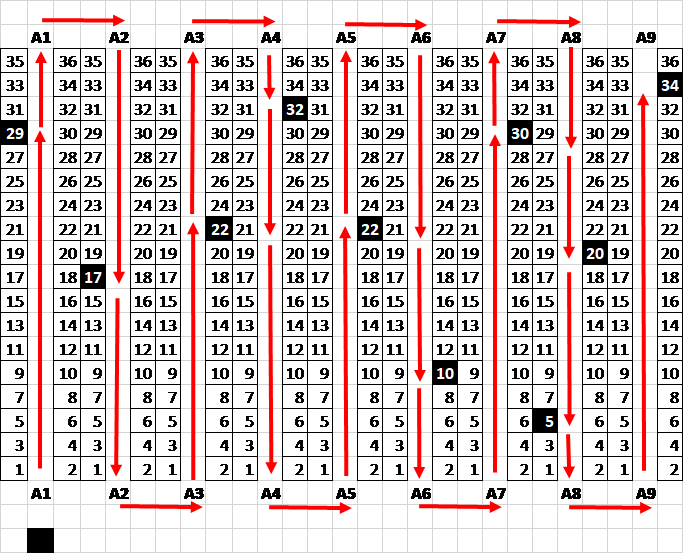

The tours are a sequence of actions of work orders to pick products. For example, let the operator has a list of work order and a numbered 10 eyed trolley. The list of work order involves products which will be placed to each numbered-eyed of trolley and addresses that products are stocked. The operator follows the orders of the list and finishes the tour. As can be seen in Figure 1, the operator walks with trolley along aisles and picks products from the identified points.

After explaining what the tour is, I am going to define the problem. As mentioned above, many stores can demand a product, but the stock of the product can be limited. For instance, let Istinye Park, Beyazit and Taksim stores of the retail company demand long-sleeved white shirts in the order of 10, 20 and 20 respectively, and its stock in warehouse is 30. Scenarios of store-product assignments which are shown with colored arrows can be seen in Figure 2.

In that case not all demand is covered and a decision is needed to be made. Istinye Park (10) and Beyazit (20) or Istinye Park (10) and Taksim (20) or Beyazit (20) and Taksim (10) can be covered. Here, to which store pairs the stock will be allocated is an optimization problem and this problem is similar with “Knapsack Problem”. Note that this part is only the product-store assignment part. In addition to this problem, if the generation of tours in the shortest distance part is added, the assignment part will take a more complex structure and the constraints will increase.

It takes a lot of time to solve this problem with classical optimization models, considering the products demanded by all the stores of the company and the related stocks. Such problems are referred to as combinatorial optimization in the literature and take longer time to solve. The main reason why such problems take a long time is the high number of decision variables. For example, 500 stores have demand for 1000 product types and these products are stocked at 1250 different locations. In this case, the number of decision variables are 625 million. The model created by these decision variables is solved under operational and theoretical constraints that include each firm’s own dynamics.

Within these constraints, the parcels sent to each store have a certain capacity and the problem must be solved so that the fullness of the parcels sent to the stores is maximum and the number of parcels is minimum.

If we added decision variables about minimum distance and assignment of trolley to mathematical model, the number of decision variables would reach the billions. Therefore, the problem cannot be quickly solved and also the solution becomes almost impossible. The company intends to solve this problem in 3–5 minutes because of replenishment operations. In other words, the new products are placed to the locations, which empty fields after the picking activities, of aisles in warehouse. Therefore, the tours have to generate by solving the problem in a short time since stock of warehouse changes instantly.

Discrete Optimization Online Course

I want to mention about the benefits of “Discrete Optimization” course which presents approaches and methods that provide short time solution about order picking optimization. This course which helps you to improve your algorithm or use hybrid approaches provides comprehensive algorithms, models and methods with challenging assignments. The level of the course is intermediate, and the course takes eight weeks to complete. The weekly assignments include different data dimensions and variety related to the problem and each solution approach varies according to the problem. The assignments consist of two phases:

- Designing algorithm of the specific problem

- Coding algorithm with Python and installing system

Therefore, your experiences of designing algorithm and coding can increase with the help of this course. Assignments in a specific week do not collide with other assignment and these assignments require your extra research. While you make an effort to obtain the solution, you can thoroughly learn and implement the approaches. You will be able to see that your algorithms or approaches solve the problems of assignments without implementing course’s approaches directly. According to the quality of your approaches, you can score 3, 7 and 10 where pass grade is 7.

The course requires base optimization knowledge and Python coding and involves methodological approaches for solutions of Knapsack Problem, Graph Coloring, Travelling Salesman Problem (TSP), Facility Location Problem and Capacitated Vehicle Routing Problem. Some of these approaches are Branch and Bound Algorithm, Constraint Optimization and Local Search Algorithm, and they have been well explained with appropriate examples.

Personal Contribution

While you work on the assignments, you can get the idea that the problem is not ever solved. Henceforward, the self-improvement starts. You are able to solve problems of assignments with searching new solution ways without despair. In addition, you can improve hybrid models with variety of machine learning models.

For instance, the solution of TSP that has a plenty of customers involves grouping customers by using k-means clustering, and finding the route that has minimum distance by using Simulated Annealing based on grouped customers. If you try to solve without customer grouping, it takes polynomial time because of the high number of customers in TSP. Likewise you are able to improve your approaches and improve yourself with other assignments of the courses.

Combining Real Problem with Theoretical Knowledge

After I was inspired from “Large Neighborhood” method that is the last subject of the course, I redesigned the picking algorithm which belongs to the retail company. This development in the new algorithm has generated 1 percent reduction of picking operations cost in comparison with previous one. The savings (millions TL) provide with an undeniable competitive advantage to the company. If friends who work in the same field with me pay special attention to this course, they will provide savings for their company. In addition to personal contribution, solving a real sector problem by using theoretical knowledge is a source of happiness for me. I wish you the same happiness …

Let me first introduce myself. I work as an Analytics Specialist for a leading retail company in Turkey. My responsibilities include improving and designing algorithms, mathematical modelling and coding, business analytics, data analytics and statistical modelling (machine learning methods etc.). I use T-SQL, Python or IBM ILOG CPLEX for the solutions and data analysis. I graduated from Mathematics (Bachelor’s degree) at Istanbul Commerce University and Management Engineering (master’s degree) at Istanbul Technical University (ITU). The title of my thesis was “Measuring comfort index in Public Transportation in Istanbul”. I have been currently focusing on “Adoption of Electric Vehicle in inner-city Freight Transportation” during my Ph.D. studies at ITU which is about to be finished.

Şükrü İMRE

Analytics Specialist & Optimization

Ph.D. (cand.) Istanbul Technical University